How to Organize Unidentifiable Manuals

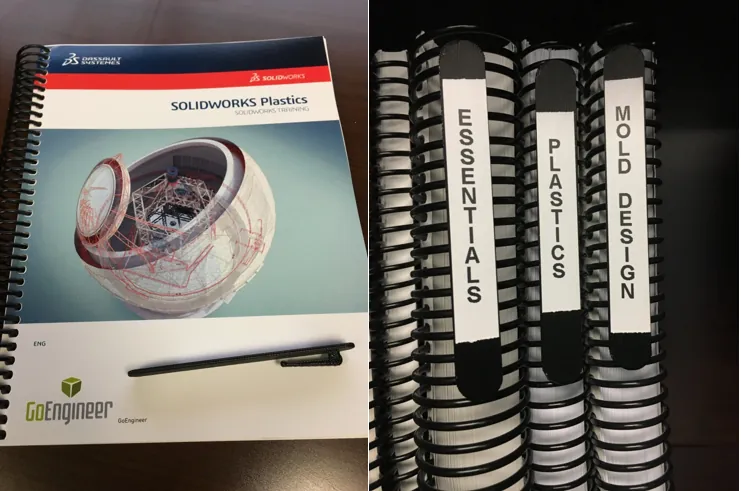

With all of the SOLIDWORK Training Classes available at GoEngineer, we instructors tend to accumulate many training manuals.

The spiral-bound manuals in my library shelves stack fine, though I find myself pulling several manuals until I find the one I am looking for. I decided that I needed to come up with a way to label these manuals so they can be easily identified.

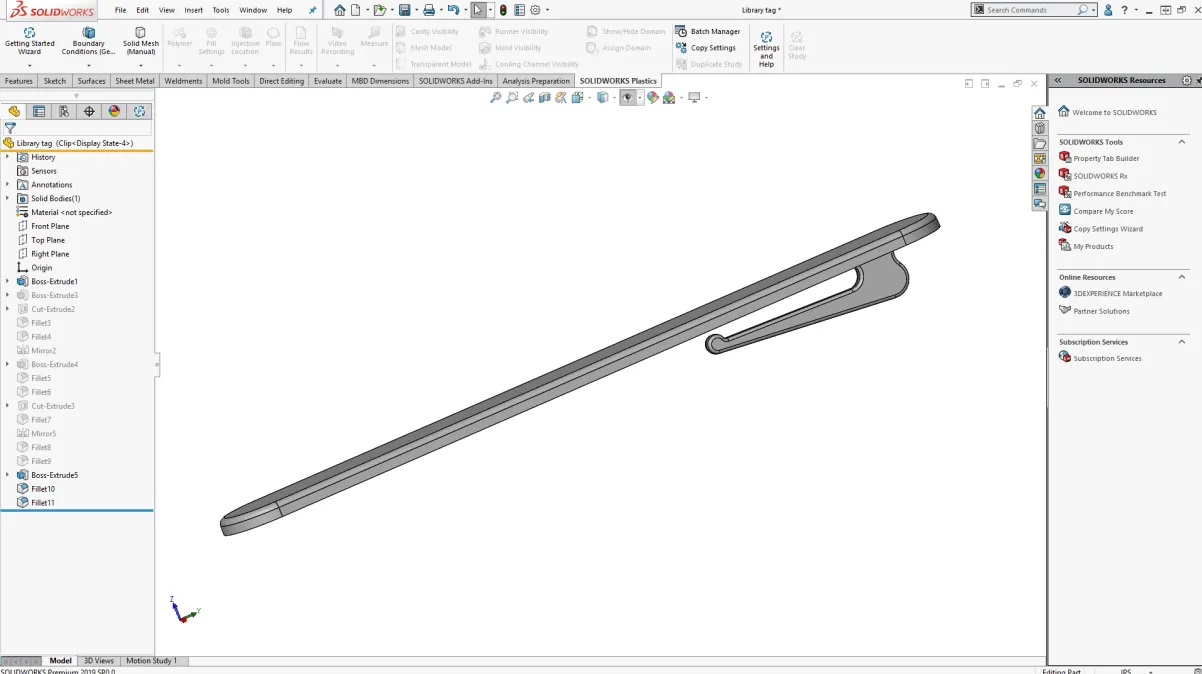

Designing the Solution

Using SOLIDWORKS 3D CAD, I designed a clip-on tag that will clip onto the spiral binding, allowing me a place to put a label. I took a couple of measurements from spiral bindings and designed this part in minutes with a couple of extruded boss/base features and some fillets.

Validating the Part

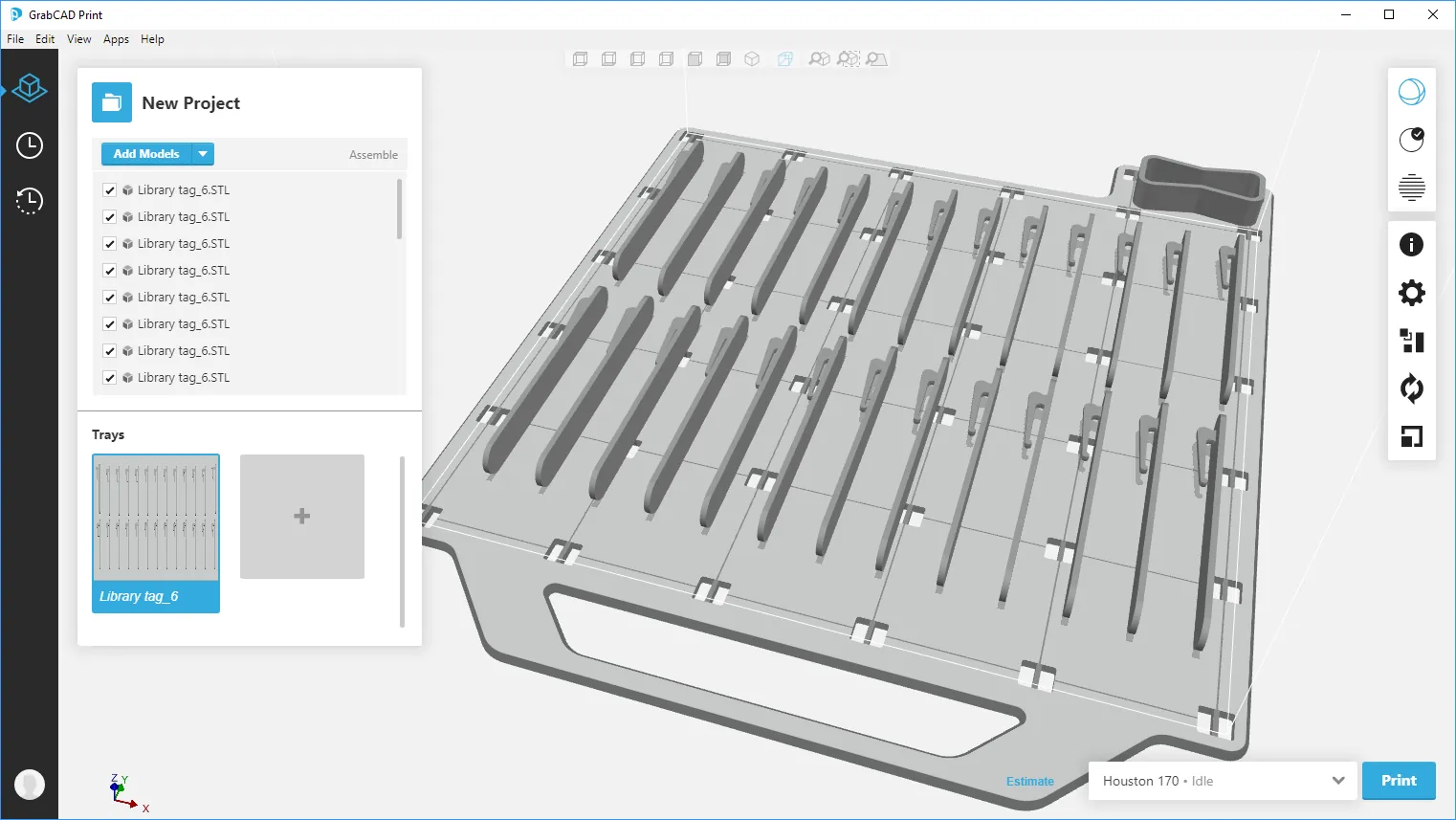

Once I was satisfied with my design, I wanted to 3D print the part to validate the fit and function. I simply opened my SOLIDWORKS model in GrabCad Print, processed the file, and sent it to the Stratasys F170 FDM printer in our office.

The print job for this one part took only 20 minutes.

The build size on the Stratasys F170 is 10″x10″ so I ran an estimate on filling the build tray. I can print an entire 10″x10″ tray of 26 parts in less than 6 hours. The parts are oriented on the tray to maximize the clips’ flex and strength.

Tagging the Manuals

The 3D printed parts fit and function as expected.

A Bonus

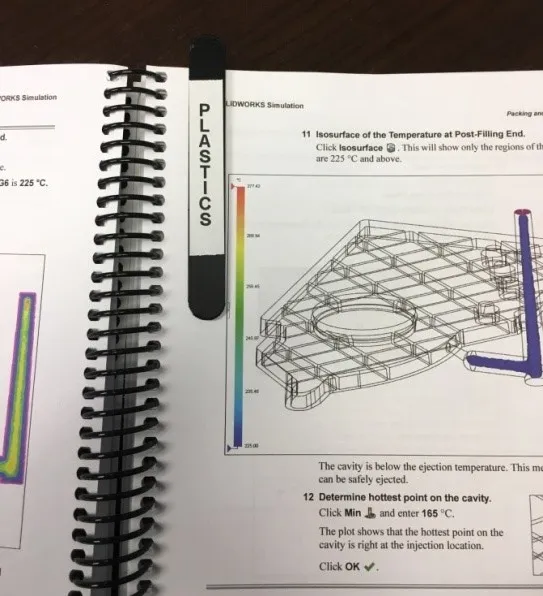

I discovered a second use for the tags: They serve as bookmarks to hold my place as I go through the training manuals.

Conclusion

By leveraging the resources available, I was able to design with SOLIDWORKS CAD, 3D print with the Stratasys F170, and test my idea to solve the problem at hand in a very short time.

Knowing that my colleagues will want some of these, I will be starting an injection molding project to produce more of them.

Look for my next blog post where I take this part model into SOLIDWORKS Plastics Simulation and SOLIDWORKS Mold Tools and then 3D print the mold cavities for injection molding.

About Jeff Lendermon

Jeff Lendermon is an Applications Engineer for GoEngineer supporting the SOLIDWORKS Plastics simulation software. Jess has over 30 years of experience in the Plastic Injection molding industry, he applies his experience and knowledge of the industry to help customers see the benefits of utilizing the tools within SOLIDWORKS Plastics.

Get our wide array of technical resources delivered right to your inbox.

Unsubscribe at any time.