The Belt/Chain Feature in SOLIDWORKS is pretty well known. If you're unfamiliar with this, check it out this video.

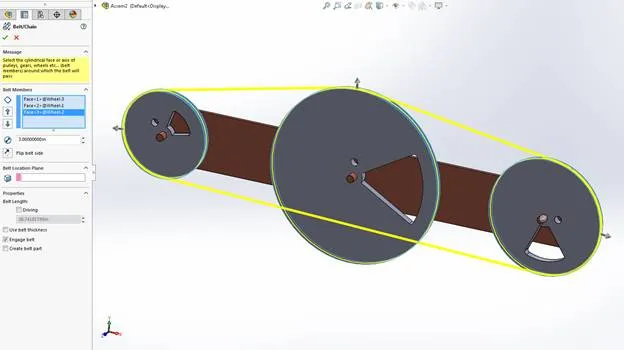

That is the basic feature, however, what if you have a situation where the chain or belt has to pass over the same wheel twice? To help clarify things, the models have been created with some holes in them to show rotation easier. See Figure 1 below as a simple example:

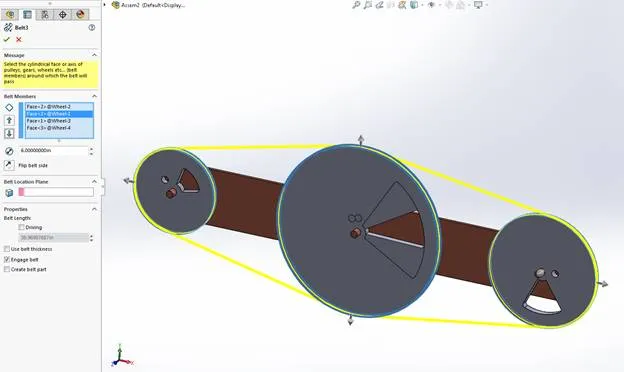

As you can see, using the Belt/Chain Assembly Feature, you can only select an item in the selection set once. So how do we get the belt to travel on the other side of the center wheel?? Well, to be honest, we have to trick the software, and it is pretty simple, really. What we do is place another copy of the center wheel at the same location as the original so we have a duplicate feature to use, see Figure 2:

This way we can now have the belt design that covers the same wheel item in the center but “touches” the wheel twice to allow a correct belt length to be calculated.

The trick at this point, and this is the really important part, is remembering to suppress the “extra” wheel if this assembly gets used in a downstream assembly. A nice configuration of the assembly called “belt design” or similar to allow the extra wheel only to be used for the function for the belt/chain design is always a great option.

Thank you for taking the time to look at this simple, quick tip from GoEngineer!