SOLIDWORKS INSPECTION

First Article & Inspection Documentation Software

What is SOLIDWORKS Inspection?

SOLIDWORKS Inspection automates the painstaking and often tedious design inspection process. The software enables you to automatically capture inspection dimensions already contained in the models and drawings that are critical to the design’s production. Generate characteristic reports, drawings with ballooned callouts, and workflows quickly and reliably—all delivered in an easy to understand format.

don't miss our upcoming webinar!

Introduction to SOLIDWORKS Inspection

Wed, Jun 9, 2021 at 10am PT

SOLIDWORKS Inspection automates the painstaking and often tedious design inspection process. The software enables you to automatically capture inspection dimensions already contained in the models and drawings that are critical to the design’s production. Generate characteristic reports, drawings with ballooned callouts, and workflows quickly and reliably—all delivered in an easy to understand format.

“ …I’m not afraid to get into any issues with my SOLIDWORKS because I know GoEngineer can/will help me fix anything.”

–

Alex Cota

Inspection Reporting Made Easy

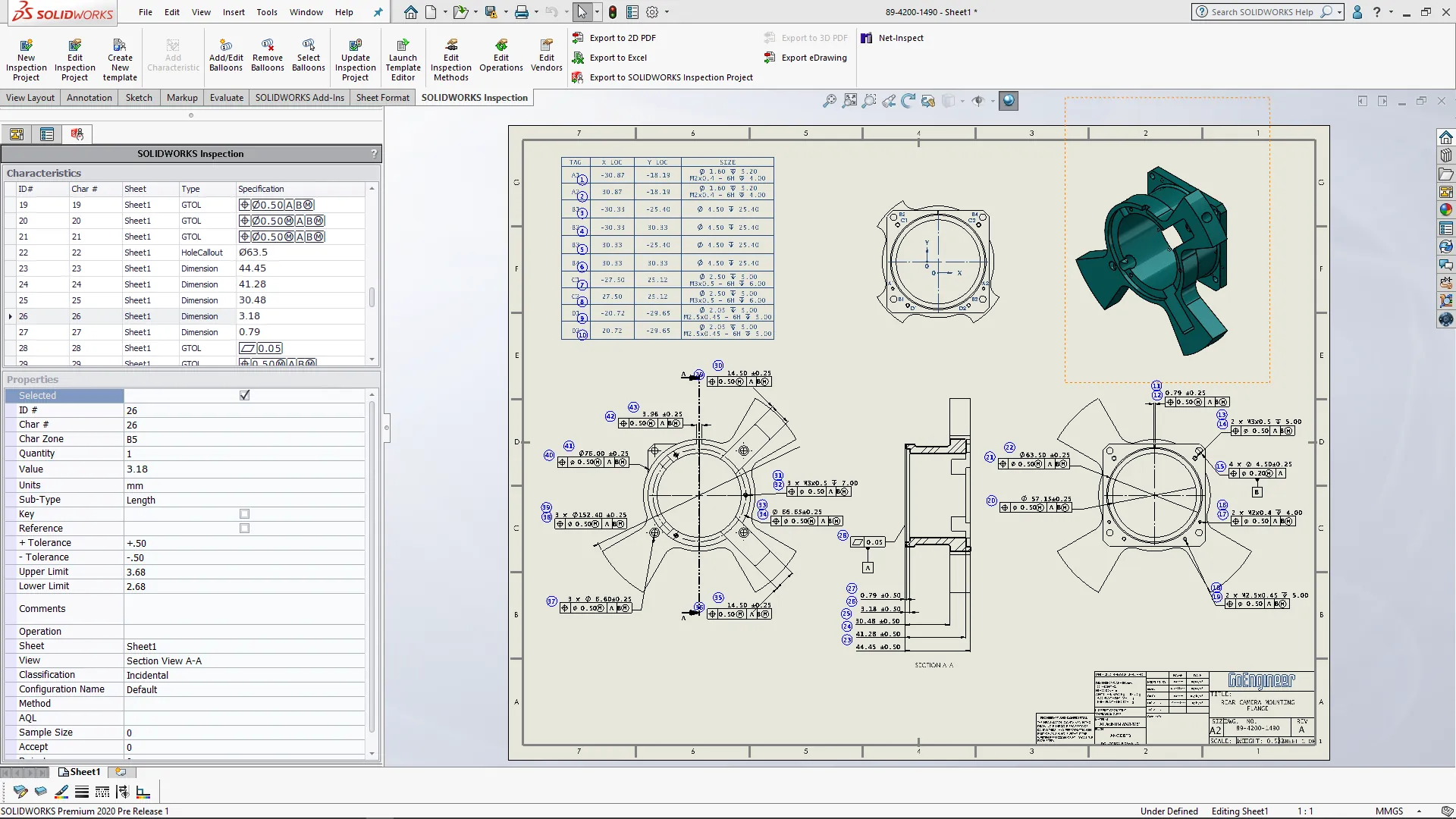

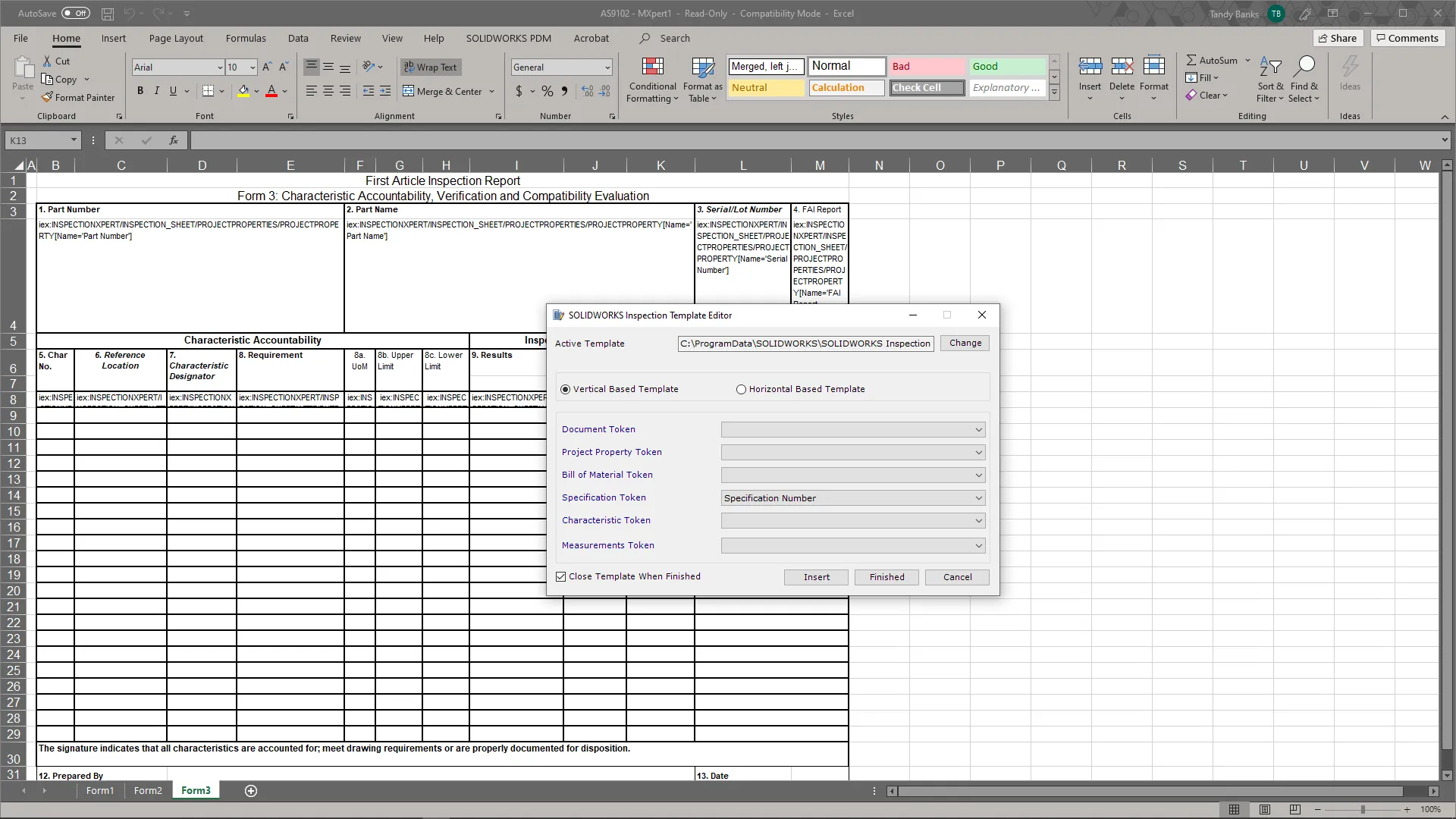

You can create industry-compliant inspection reports or use the powerful template editor to develop a report that matches your company’s needs. The flexibility in reporting allows you to compile multiple measurement methods into one report while seeing visual feedback on compliance status. Create inspection documents from SOLIDWORKS models and drawings or from any standard CAD system using standalone SOLIDWORKS Inspection. Export inspection reports to Microsoft Excel using standard templates.

Tools

SOLIDWORKS INSPECTION

Advanced tools to help expedite first article and in-process inspection reports.

Custom Project Templates

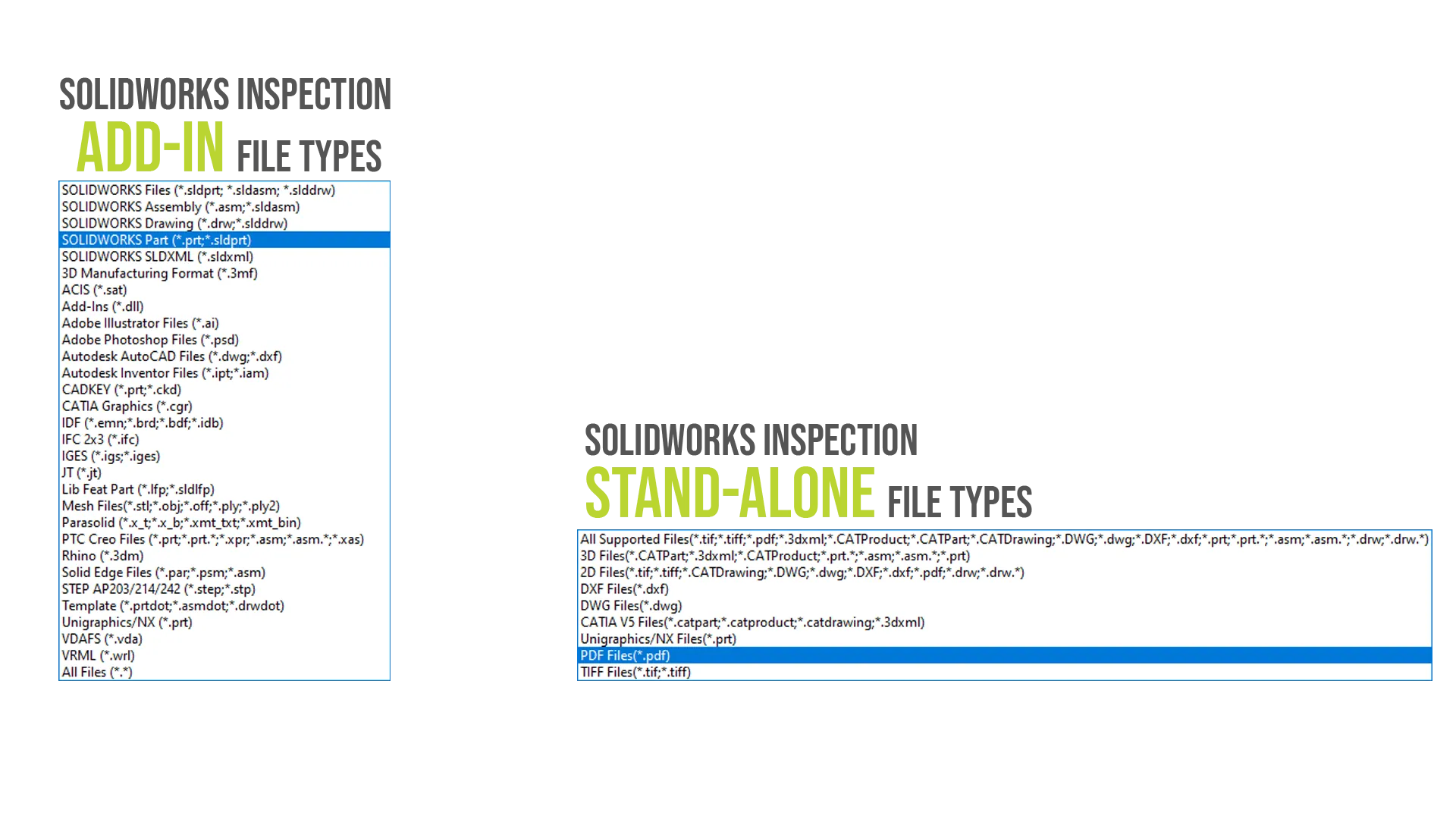

SOLIDWORKS Inspection allows custom project templates to be pre-configured to utilize the model or drawing properties that are important to your organization’s needs. The built-in template editor guides the process of building robust report templates. The software can also work with a variety of drawing file types (not just PDF & SOLIDWORKS documents) in both the standalone and add-on versions of SOLIDWORKS Inspection.

Automate Data Entry

Set the parameters only once in SOLIDWORKS Inspection’s templates to follow company or industry standards. Each time the custom template is used, the data automatically populates in the correct location, increasing accuracy and reducing the time it takes to train machine operators and inspectors.

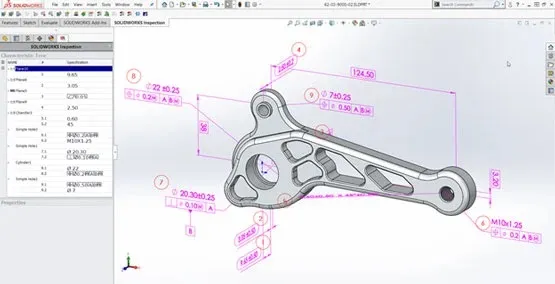

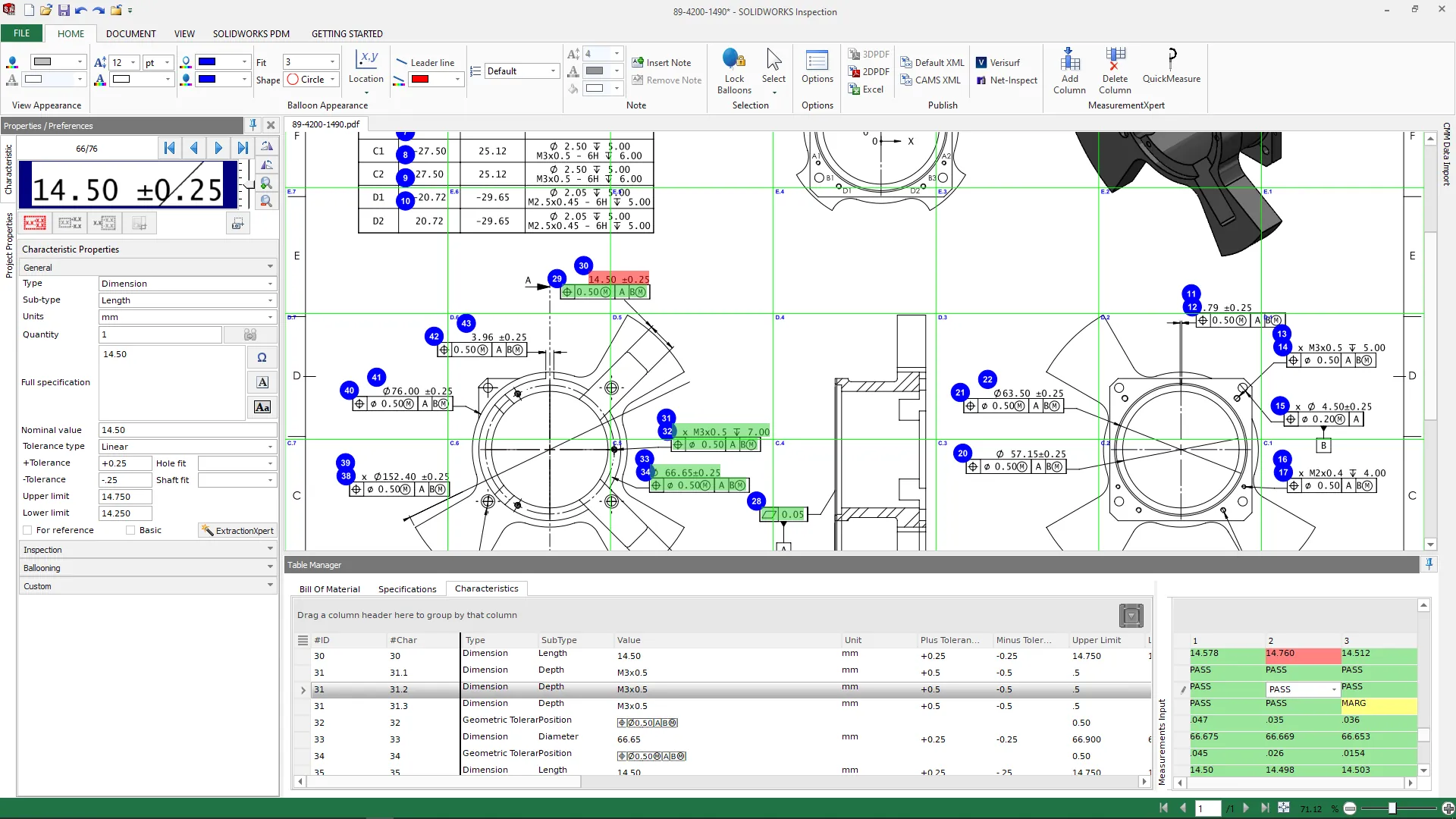

Balloon Inspection Dimensions

Automatically balloon inspection dimensions and capture characteristic features with a few clicks. The data is pulled from the product and manufacturing information (PMI) on the drawing or model. Tasks that may have taken days using Excel to copy and paste data are now reduced to a few minutes—freeing important resources to focus on more critical tasks.

Quality Reports Made Easy

Most people don’t get into engineering, manufacturing, or quality because they like building reports of characteristics and measurements. With SOLIDWORKS Inspection, both the standalone and plugin version does its job so well that it makes working with this type of technology fun. What is better than getting a quality job done in a timely manner?

Frequently Asked Questions

SOLIDWORKS INSPECTION Features

Fast & Accurate Quality Documents

SOLIDWORKS Inspection provides the tools to quickly produce ballooned drawings, first article, and in-process characteristic reports. Models and drawings typically use an abundance of dimensions, notes, symbols, and frames that depict the importance of features during production. SOLIDWORKS Inspection software understands how to interpret each feature and can organize them into quality reports. Using templates that meet your needs, the software builds reports and ballooned drawings in minutes. Hours can literally be saved on each part number leading to more efficient workflow, reduced costs, and improved communication between engineering and production departments. Couple Inspection with SOLIDWORKS MBD (Model-based definition) software and the time savings get even better.

Works Seamlessly with Many File Types

It’s common to share design information in a PDF or TIFF file of drawings and models. SOLIDWORKS Inspection also recognizes the embedded product manufacturing information (PMI) data in STEP AP 242, PRT, ASM, and DRW file formats. There’s support for CATIA’s CATPart, CATProduct, CATDrawing, and 3DXML. DXF & DWG drawings can be added to the projects, too. Once you extract the needed characteristics from these files, the data can be compiled into reports that can be saved as Excel (XLS), CSV, or XML.

Consolidate Reports

Some products require numerous measurement methods to completely verify compliance. SOLIDWORKS Inspection Professional’s capability to gather input from manual entry, digital devices, or CMMs makes it a great tool to quickly collect data all into one place. The measurement input cells can be set to color-code to highlight features that are compliant in a pass/marginal/fail scale. The captured area of the characteristic will match the color-coding of the cell making it easy to see measurements that may be non-compliant. All data entered in these cells can be displayed in the report export along with its red, yellow, or green (default) coloring scheme.

Build Report Templates

Combine the power of Excel spreadsheets with the data of SOLIDWORKS Inspection projects to build great reports. The template editor allows you to edit one of the included templates, build your own from scratch, or convert one of your existing forms. Data is segmented into project properties, characteristic features, bill of material fields, measurement values, specification details, and document properties. Each of these can be embedded into the Excel templates at the appropriate places in your forms. All formatting of the cells, borders, fonts, and justifications can be set using commonly known Excel tools. Formulas can be derived and react to the data as its programmatically placed from the SOLIDWORKS Inspection project data.

"...friendly attitude and talked me through the problems perfectly. Everyone I've dealt with at GoEngineer when needing support has always been friendly and courteous. Two thumbs up indeed!!”

- Matthew Grace

Compare SOLIDWORKS INSPECTION

STANDARD

Professional

Create Inspection Reports

Optical Character Recognition

PDF Drawing Comparison and 2D/3D Revision Management

Quality Sampling Plans

Export Options

Automatic Ballooning

Customize Inspection Reports

File Management

Enter and Import Measurements

Highlight Critical Dimensions

SOLIDWORKS Part/Assembly File Support

2D/3D CAD File Support

Inspection Measurements

Graphical Pass/Fail Status

SOLIDWORKS Services:

Utilize GoEngineer’s Award Winning Support & Training for SOLIDWORKS

Award Winning Technical Support

GoEngineer's extensive SOLIDWORKS technical knowledge and world class support can help you succeed with SOLIDWORKS. Our award-winning team is ready to help you with any task you may have. Using state-of-art remote assistant technology software allows our team to solve most issues within one session. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

- 125+Certified Technical Specialists

- Email, Phone and Chat Support Available

- 98% Exceptional Customer Service Rating

PROFESSIONAL SOLIDWORKS TRAINING

GoEngineer offers online and classroom professional SOLIDWORKS training for organizations and individuals. All our instructors are SOLIDWORKS certified and teach thousands of students each year world wide. The curriculum is very diverse with numerous certified SOLIDWORKS courses to choose from. Each student will receive a Course Completion Certificate and preparation materials for SOLIDWORKS certification.

- Increase Your Earning Potential

- Led by Certified SOLIDWORKS Instructors

- Smaller Classes with Focused Attention

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here. Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A. WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet and SL 3D printers. 3D Printing Services